Toy Companies Moving from China to India

Syllabus: International Relations (GS Paper-2)

Context

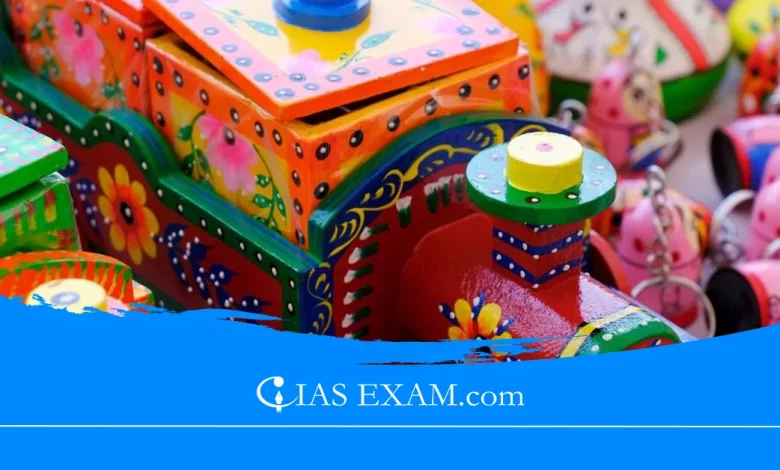

- The toy industry in India has witnessed this growth trajectory in recent years. Exports have shot up by 239 percent, while import figures have fallen by 52 percent. This has made India a net exporter and provoked the toy companies to move from China to India.

- Global majors such as Hasbro, Mattel, Spin Master, and Early Learning Centre are highly dependent on India for sourcing. Shifted their age from China to India. A decade ago, India was a negligible market for toy sourcing. Furthermore, domestic toys have consumed much of the space that imports once held. Major manufacturers have set up shop in India.

Factors Influencing the Shift of Toy Manufacturing from China to India

- Cost and Efficiency Concerns: Rising labour costs of China, as witnessed by the toy manufacturers, are an evident factor for the shift in the production locations. Anyway, the foremost problem is to reach the above- mentioned threshold. Though India since a long time has been providing a competitive edge over China due to its cheap labour costs, its disadvantage lies in infrastructural provisions ranging from ports to road facilities where it still lags behind China.

- Impact of the COVID-19 Pandemic: The pandemic made it clear that having an excessively heavy production scheme dependent on one country, be it China, leads to similar disruptions in the supply chain. Chinese ports shutdown and delays brought the halt to moving freights, now companies go ahead to think of diversifying their manufacturing location.

- Investment Trends: There had been an enormous movement of greenfield investment which formerly used to be focused on China that was now being repositioned towards India. A study showed that US and EU investment into India rose from a total of $65 billion accounting for the last two years as compared to a $2.2 billion dip in investment into China.

- Market Dynamics in India: Over recent times, the share of Indian toy manufacturers has been growing very fast, leading to decreased position of Chinese toys imports. ‘Make in India’ and the promotion of industrial free zones are some of the policies that saw the huge advance. Indian made toys are often moved forward for their quality and competition with Chinese accomplishes their task.

- Government Policies and Industry Growth: The Indian government should prepare the policies for the Toy industry and set up the schemes to promote the Toy industry. Both leading businessmen urge governmental officials to take appropriate steps towards expansion of legitimate trade and diminishing illegal imports.

Guidelines by Indian Standards on Toys

-

- Mandatory Quality Control Order: The Toys (Quality Control) Order, 2020 mandates that all toys for children under 14 years must conform to specific Indian Standards and bear the ISI Mark under a licence from BIS. This order became effective from January 1, 2021.

- Seven Key Standards for Toy Safety:

-

- IS 9873 (Part 1): 2019 – Safety aspects related to mechanical and physical properties.

- IS 9873 (Part 2): 2017 – Flammability requirements.

- IS 9873 (Part 3): 2020 – Limits for the migration of certain elements.

- IS 9873 (Part 4): 2017 – Safety of swings, slides, and similar activity toys.

- IS 9873 (Part 7): 2017 – Requirements for finger paints.

- IS 9873 (Part 9): 2017 – Limits for certain phthalate esters.

- IS 15644:2006 – Safety of electric toys.

- Testing and Certification: BIS licences toy manufacturing units based on their manufacturing and testing capabilities, which include factory visits and toy testing in BIS or BIS-recognized labs. Toys undergo rigorous testing for choking hazards, sharp points, toxic elements, and electrical safety aspects.

- Regular Surveillance and Compliance: BIS conducts regular surveillance visits at licensed manufacturing units and tests samples drawn from factories and markets to ensure compliance with the safety standards.

- Consumer Awareness: Consumers are encouraged to purchase toys bearing the “ISI Mark” to ensure safety and quality. Non-compliance can be reported through the BIS Care app or by contacting BIS directly.

Conclusion

Due to increased labour costs in China and a desire for other manufacturing choices, the Chinese toy industry is moving to India. India’s huge labour force and potential for expansion is evident but infrastructure and supply chain efficiency has been an obstacle which must be overcome. India is changing global manufacturing patterns with this move, and for once takes a significant position in the game.

Source: Business Standard

UPSC Mains Practice Question

Examine the reasons behind the recent shift of global toy majors from China to India, highlighting the potential impacts on the global toy industry, as well as the challenges and opportunities this presents for India’s economic growth and manufacturing sector. Analyse how this shift aligns with the ‘Make in India’ initiative and discuss the measures needed for India to fully capitalise on this opportunity. [250 Words]

.png)